12

ISSN 2477-9105 Número 24 Vol.1 (2020)

La exergía determina la pérdida de energía real con mayor precisión que un balance de energía

tradicional; además, el manejo económico – energético se convierte en un aspecto de gran

relevancia, que correlaciona criterios técnicos y de optimización. El objetivo de este estudio fue

realizar un análisis exergético de la planta pasteurizadora de leche en la Estación Experimental

Tunshi,- Chimborazo para la determinación de puntos de mayor destrucción de exergía en las

líneas principales de pasteurización de la estación las que son estandarización y pasteurización,

generación de vapor y sistema de frio. Los datos de cada línea del proceso se recolectaron durante

un mes en operación normal y sacando las ecuaciones del sistema completo utilizando el programa

enginner equation solver. Los resultados indicaron que la mayor tasa de destrucción de exergía en

la línea de pasteurización estuvo en el intercambiador de calor de placas (29,42 kJ s

-1

), debido a las

diferencias de temperatura en el choque térmico para la pasteurización, en la línea de generación

de vapor fue en la caldera debido a las pérdidas de calor (5,14 kJ s

-1

) y en la línea del sistema de

enfriamiento se dio en el banco de hielo por la transferencia de calor rápida (0,21 kJ s

-1

). De acuerdo

con los resultados del presente estudio, los parámetros de desempeño y sostenibilidad de las plantas

procesadoras de productos lácteos pueden ser mejor evaluados y mejorados; como se sugiere a

través de la utilización de mejor aislante térmico orientado y optimizando los intercambiadores de

calor.

Palabras claves: Exergía, Destrucción exergética, Optimización, Pasteurización, Eficiencia.

R

esumen

A

bstract

The exergy determines the loss of real energy more accurately than a traditional energy balance;

In addition, economic-energy management becomes an aspect of great relevance, which correlates

technical and optimization criteria. The objetive of this study was to perform an exergy analysis

of the milk pasteurization plant in the Tunshi Experimental Station, - Chimborazo for the

determination of points of greater destruction of exergy in the main lines of pasteurization of

the station which are standardization and pasteurization, steam generation and cold system. The

data of each line of the process was collected during a month in normal operation and taking

the equations of the complete system using the program engineer equation solver. The results

indicated that the highest destruction rate of exergy in the pasteurization line was in the plate heat

exchanger (29.42 kJ s

-1

), due to temperature differences in the heat shock for pasteurization, in the

steam generation line was in the boiler due to heat losses (5.14 kJ s

-1

) and in the cooling system

line was given in the ice bank by rapid heat transfer (0.21 kJ s

-1

). According to the results of the

present study, the parameters of performance and sustainability of the dairy processing plants

can be better evaluated and improved; As suggested through the use of better thermal insulator

DETERMINACIÓN DE PUNTOS DE OPTIMIZACIÓN A TRAVÉS DE

BALANCE DE EXERGÍA EN LA PLANTA DE PASTEURIZACIÓN

DE LECHE “ESTACIÓN EXPERIMENTAL TUNSHI (RIOBAMBA –

ECUADOR)”.

Determination of energy optimization points by exergy balance in the milk pasteurization

process in the "Tunshi Experimental Station (Riobamba-Ecuador)".

Paola Angamarca, Daniel Antonio Chuquin Vasco, Paul Palmay Paredes*

Escuela Superior Politécnica de Chimborazo, Facultad de Ciencias, Carrera de Ingeniería Química,

Riobamba, Ecuador.

* paul.palmay@espoch.edu.ec

13

Angamarca, Chuquin, Palmay

I. INTRODUCTION

At present, milk and its products are one of the

most consumed products worldwide. Based on

the predictions of the study carried out by the

Food and Agriculture Organization of the United

Nations (1), it is estimated that milk production

in 2016 was 816 million tons. In terms of energy,

the dairy industry is one of the most energy con-

suming in its production process and that energy

is based mainly on the use of fossils, which ge-

nerates the emission of greenhouse gases (CO

2

,

SO

x

, NO

x

), at considerable scales (2). The increa-

se in energy efficiency is a challenge for this type

of industry, and in this sense the use of renewa-

ble energy and / or the optimization of non-re-

newable energy during the production process,

would promote the reduction of gas emissions

and at the same time the protection of the en-

vironment (3). The global energy resources are

limited, for this reason energy efficiency policies

were analyzed and the interest of the scientific

community in the development of energy con-

version devices and new techniques that allow

better use of existing resources to avoid waste (4)

Because of the importance involved in optimi-

zing energy efficiency, in the last decades indus-

tries have applied energy and exergy balances to

analyze consumption and improve the efficiency

of the available energy resources of fossil fuels

(2). The exergy analysis is considered as an effec-

tive tool to evaluate the performance of a system,

the result of the analysis quantifies the real ener-

gy losses (destruction and exergy efficiency) and

provides a measure of energy quality (5), (6). The

exergy, unlike the 1

st

Thermodynamic Law (Law

of Conservation of Energy), is not conserved du-

ring the whole process (2nd Law of Thermodyna-

mics) and is defined as the work available for use

by a system (7), (8). According to (9), the exergy

balance determines the actual energy loss more

accurately compared to the traditional energy

analysis in a production plant. In other words,

the exergy analysis evaluates the sustainability

and performance of energy systems. As reported

by (3), the increase in the exergy efficiency of a

system decreases its environmental impact and

increases its sustainability index and vice versa.

With regard to the dairy industry, there are se-

veral investigations that have focused on ener-

gy / exergy analysis. For example, (10) applied

an analysis of exergy and advanced energy in a

dairy industry, the study suggested that exergy

analyzes especially avoidable and inevitable exer-

gy can contribute to a better understanding of the

real process and the way to focus optimizations

during the process. (11) carried out a thermody-

namic analysis of the process of pasteurization

of milk from geothermal energy in which they

determined that the exergy efficiency of the pro-

cess at different temperatures was in the range of

22.61 to 56.81%. (2) developed a comprehensive

analysis of an industrial scale yogurt production

plant composed of 4 lines (steam generation, re-

frigeration, standardization and pasteurization

of milk), in the study it was found that the com-

pressor set air / heater is where the greatest exergy

destruction occurs (12484.88 kW) and the lowest

exergy efficiency (8.48%).On the other hand, (12)

conducted an investigation of how exergy balan-

ce can be a potential tool to analyze and optimize

dairy processes in terms of energy.

From the study it was determined that the exer-

gy efficiency is in the range of 36-99% observing

greater exergy loss in the evaporators and dryers.

The production of pasteurized milk in the Tuns-

hi experimental station, consists of three main

lines: steam generation, refrigeration, standardi-

zation and pasteurization of milk. The main ob-

jective of this research was to perform an exergy

balance of each line and identify the maximum

work according to the needs that the plant re-

quires, in order to reduce the different types of

energy losses in the equipment and achieve a

product that complies with quality standards, to

maximize the benefits of the plant and provide a

profitable value to the product (15)

oriented and optimizing heat exchangers.

Keywords: Exergy, Exergy destruction, Optimization, Pasteurization, Efficiency

Fecha de recepción: 08-07-2019 Fecha de aceptación: 31-03-2020 Fecha de publicación: 24-04-2020

14

ISSN 2477-9105 Número 24 Vol.1 (2020)

II. MATERIAL AND METHODS

General operating conditions

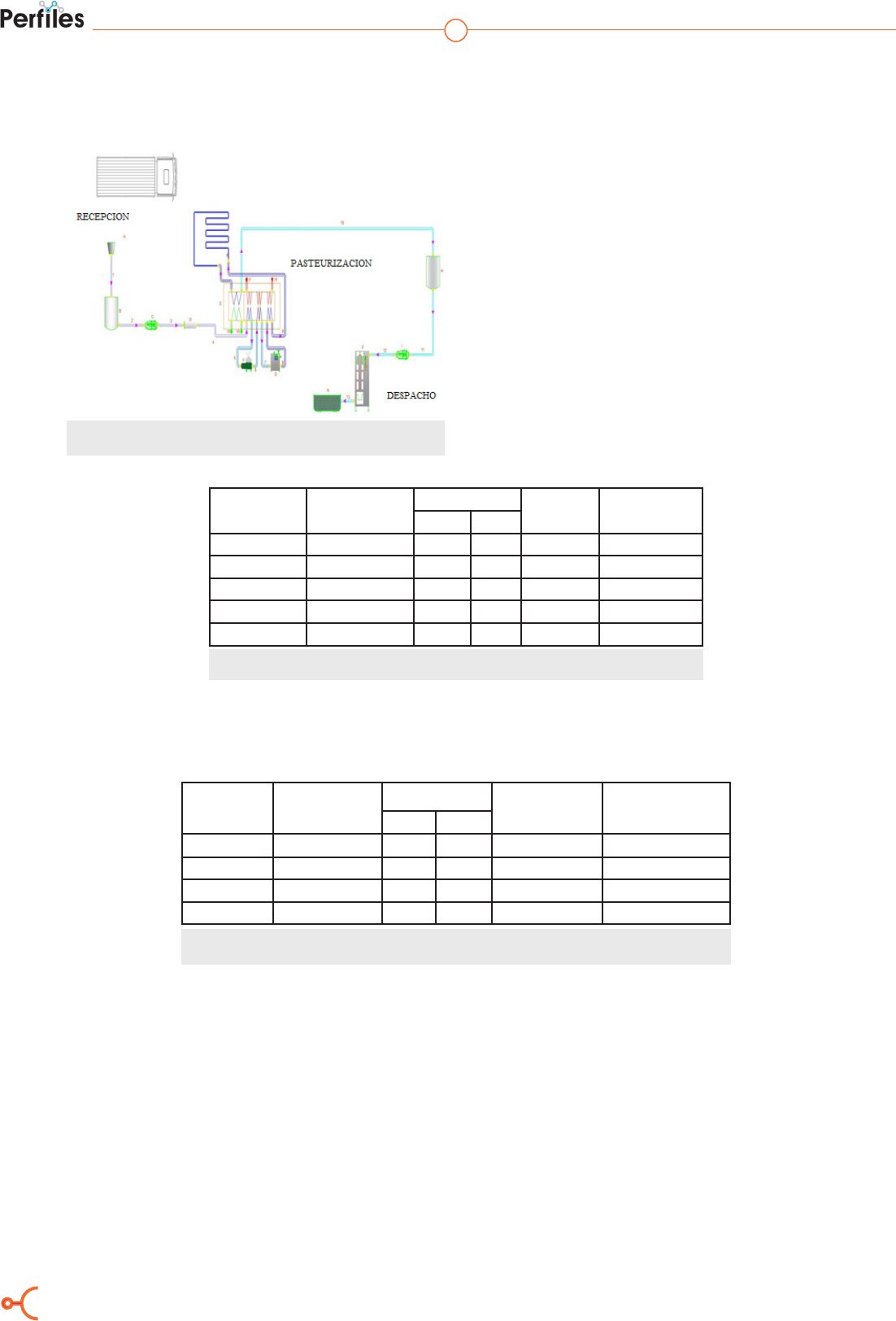

Figure 1. General Scheme of the Plant

Source: Authors

The steam generation has a cauldron with a

power of 11200 W, the control is automatic, the

maximum pressure is 55 psi and the minimum

is 45 psi.

The steam that is generated is directed towards

the processing plant by a pipe covered with glass

wool to avoid heat losses.

The cauldron consumes 2.19x10-4 L s-1 of diesel,

the water enters the cauldron at 313.15 K and wa-

ter vapor comes out at 400.15 K, the steam con-

denses at a temperature of 350.15 K and enters

the heat exchanger by plates, to increase the tem-

perature of the milk that returns to the cauldron

(Table 1).

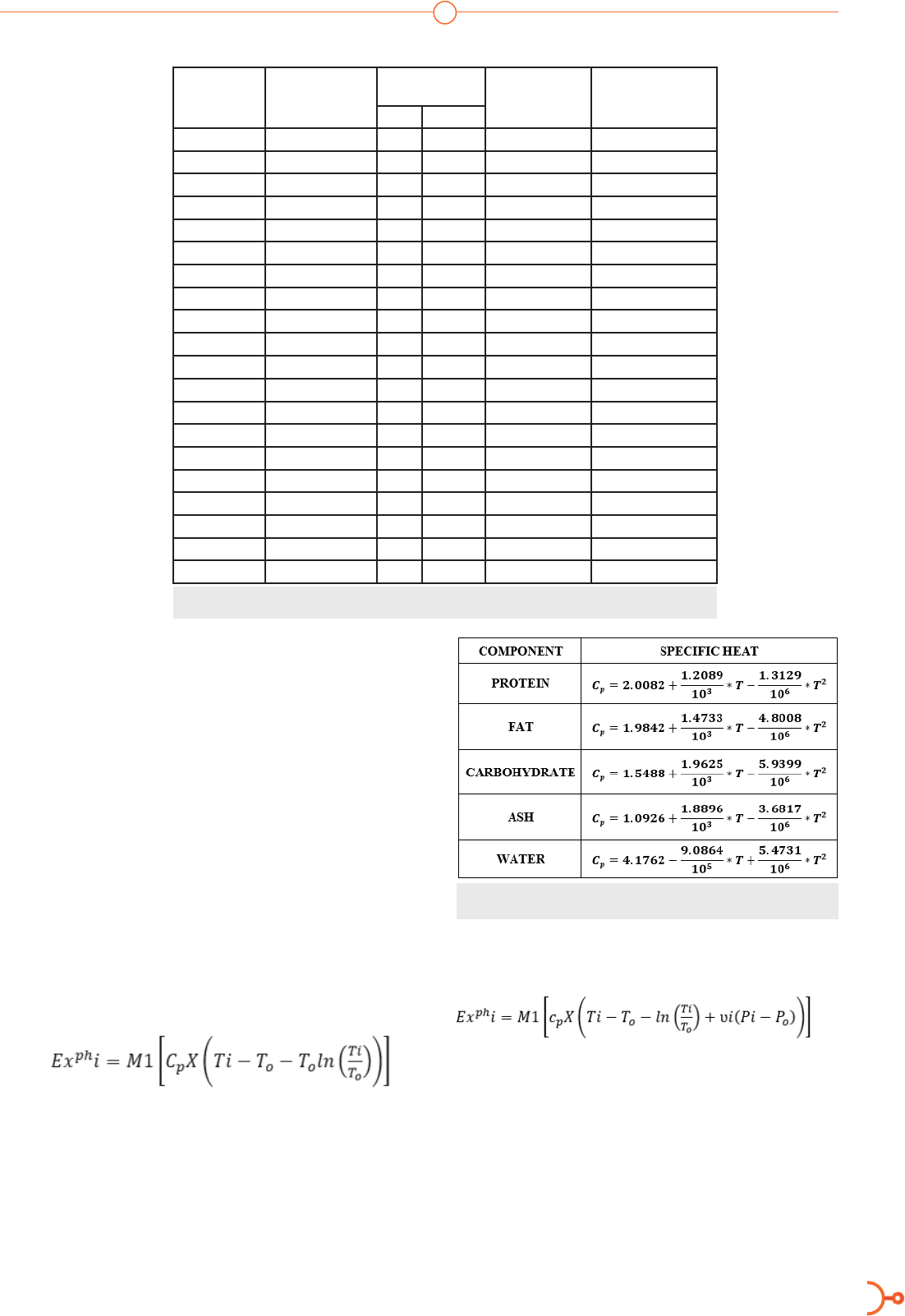

Nº CURRENT TYPE OF FLUID TEMPERATURE PRESSURE

(kPa)

MASS FLOW

(kg s

-1

)

(ºC) (K)

I Wat er 40 313.15 74.233 0.0136

II Water vapor 127 400.15 310.264 0.0136

III Hot water 87 360.15 870.264 0.0136

IV Hot water 91 364.15 1090.012 0.0136

V Hot water 79 352.15 340.354 0.0136

Table 1. Steam generation line data

Source: Authors.

The cooling system needs an ice bank that allows

the plant to have cold water. The water is at

290.15 K and decreases to 277.15 K when passing

through the ice tank (Table 2).

Nº CURRENT TYPE OF FLUID

TEMPERATURE

PRESSURE (kPa) MASS FLOW (kg s

-1

)

(ºC) (K)

IX Wate r 16 289.15 83.233 0.080

VI Frozen water 4 277.15 85.201 0.080

VII Frozen water 5 278.15 290.348 0.080

VIII Frozen water 5 278.15 250.348 0.080

Table 2. Cold line data

Source: Lopez, (2014).

The pasteurizer with plate exchanger has a water

expansion tank, which controls the temperature

of the water that enters a section of the plates,

this is controlled by an automated sensor so that

the milk can get warm and go to the centrifu-

ge with a temperature of 308.15 K leaving at a

temperature of 338.15 K, the milk flow returns

to the pasteurizer so that the temperature of the

milk rises to enter the homogenizer with a tem-

perature of 343.15K, the milk leaves at 355.15 K

and returns to the regeneration process by 10 sa

358.15 K to move to the cooling stage. The drop-

in temperature is obtained with cold water that

circulates through another section of the plates

at 277.15 K. Once the pasteurized milk is trans-

ferred to a storage tank with a capacity of 2000

L, stainless steel tank with thermal insulation to

maintain the temperature of the pasteurization,

the milk to be sheathed reaches 292.15 K to be

sent to its destination (Table 3).

15

Standardization and pasteurization line

To obtain data from this line, reference was made

to an ambient pressure (Po) 1 atm and room tem-

perature (T0) of 298.15 K.

Reception and storage tank : According to (16),

in order to analyze the exergy of a mixture it is

necessary to determine the amount of heat that

is transferred between the components and their

surroundings until the dead point that will be

the reference state expressed as a function of the

calorific capacity at constant pressure of each

component of a mixture. For the raw milk that

enters the tank you can define your physical

exergy (17) :

(1)

Where : M1 : mass flow whole milk, CpX : heat

capacity of milk, temperature current (i)(K), To

ambient temperature (K).

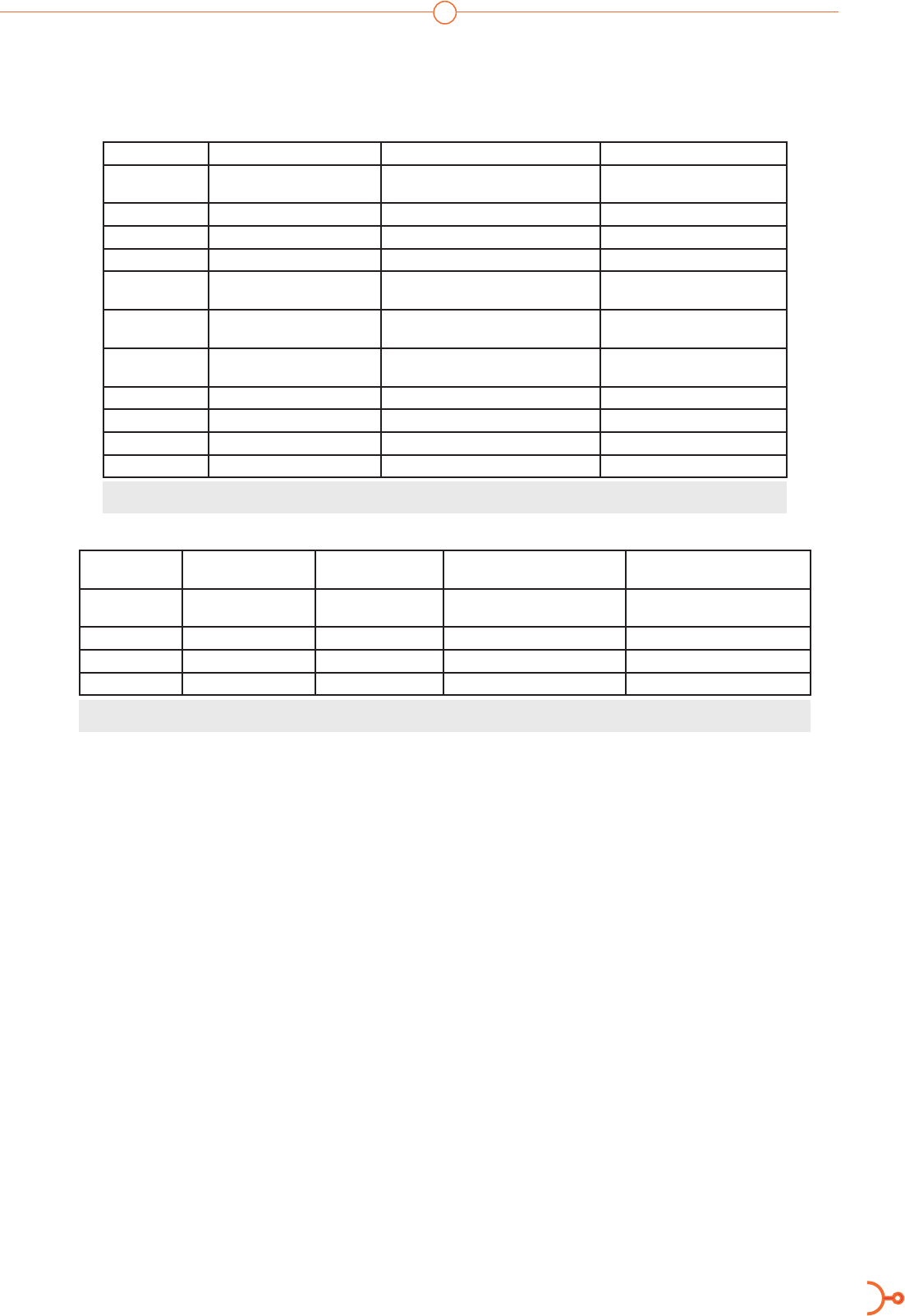

The heat capacity according to (17) of the Equa-

tion 1 can be taken from the mathematical equa-

tions detailed in the Table 4:

Table 2. Heat Capacity

Source: Wolosz, 2018

Pumping, Filter and Centrifuging Devices: De-

pending on the reversible work of the devices,

the exergy was calculated from Equation 2.

(2)

Where : M1 : mass flow whole milk, υ especific

volumen current (i), pressure current (i), atmos-

pheric pressure (i).

Homogenizer: Equipment of 6.7 kW of power and

capacity of 1200 L/ h has a set of pistons for milk

fattening by reducing the size of the fat globule.

In order to determine the chemical exergy that

accompanies milk in any part of the process, it is

Nº CURRENT TYPE OF FLUID

TEMPERATURE

PRESSURE

(kPa)

MASS FLOW (kg

s

-1

)

(ºC) (K)

1 Whole milk 17 290.15 74.233 0.041

2 Whole milk 17 290.15 74.233 0.041

3 Whole milk 17 290.15 75.233 0.041

4 Whole milk 16 289.15 600.420 0.041

5 Whole milk 21 294.15 590.420 0.041

6 Whole milk 22 295.15 13000 0.041

7 Skimmed milk 65 338.15 13000 0.041

8 Skimmed milk 70 343.15 700.709 0.041

9 Skimmed milk 82 355.15 400 0.041

10 Pasteurized milk 85 358.15 400 24.72

11 Pasteurized milk 85 358.15 400 24.72

12 Pasteurized milk 5 278.15 400 24.72

13 Pasteurized milk 5 278.15 410 24.72

14 Pasteurized milk 7 280.15 1100 24.72

15 Layered milk 7 280.15 74.233 24.72

16 Layered milk 169 289.15 74.233 24.72

IV Hot water 93 366.15 380.354 0.0136

V Hot water 79 352.15 340.354 0.0136

VI Frozen water 4 277.15 85.201 0.080

VII Frozen water 4 277.15 170.348 0.080

Table 3. Pasteurization line data

Source: Lopez, (2014).

Angamarca, Chuquin, Palmay

16

ISSN 2477-9105 Número 24 Vol.1 (2020)

necessary to establish the composition in each of

the lines with the data in Table 4.

(18) took the standard chemical exergy of the in-

organic materials present in milk. On the other

hand, the semi-empirical mathematical model

used by (16) was used for organic components.

This indicates the need to analyze from the ther-

modynamic view the possible structural confi-

gurations that milk will have depending on its

composition and that can be determined for the

case of the homogenizer depending on the dia-

meter of the fat globule:

(3)

Where: Sconf = Configurational entropy, -N =

Number of scattered drops per kilogram of milk,

KB = boltzmann constant, O = Volume of the

dispersed phase.

The value of N was established by a laboratory

test, for this was used: One liter of milk, a large

pot, a jar. The liter of milk was dropped into the

pot at a height of 30 cm, the drops that splashed

were counted the number of scattered drops as

well, 5 tests were performed to eliminate outliers.

Steam generation system

The line consists of a boiler, a condenser and a

pump. To determine the mass flow of the boi-

ler, the power and a mass flow of 0.01 kg s

-1

were

taken as reference. The fuel used is diesel (C

12

H

26

)

with a mass flow of 5.25 x10

-2

kg s

-1

y and with a

steam production of 2.00x10

-4

L s

-1

(19).

The Equation 4 is used to calculate the physical

exergy of currents of water and steam of the

system:

(4)

Where: Exph I physical exergy at the entrance of

the boiler (kJ s

-1

), M3 mass flow of the steam ge-

neration system (kg s

-1

), T0 ambient temperature

(K), h1 enthalpy at the entrance of the boiler, ho

enthalpy at ambient temperature (kJ kg

-1

), S1 en-

tropy at the entrance of the boiler, So entropy at

ambient temperature (kJ kg

-1

).

The chemical exergy of the fuel that enters the

boiler is determined from the Equation 5:

(5)

Where: Md

3

is the mass flow of fuel (kg s

-1

),

O1fuel quality factor (kg s

-1

), qLHV Minimum

bottom heat of fuel. According to (16), the quali-

ty factor (O

1

) of hydrocarbon fuels such as CaHb

is approximated by the application of an empiri-

cal equation.

The molar percentages leaving the boiler were

determined based on the chemical reaction of

combustion with theoretical air and assuming

complete combustion, to determine its chemical

exergy.

(6)

Based on the chemical reaction of the Equation 6

the chemical exergy at the boiler outlet is deter-

mined with the Equation 7.

(7)

Where, Md

3

is the diesel mass flow, N

1

total num-

ber of moles, Xi molar fraction, Ei standard che-

mistry exergy, R Universal constant of the gases

(kJ mol

-1

K

-1

) and To the Ambient temperature K.

Refrigeration system

The line consists of an ice bank and a pump. The

ice bank works with a single-phase motor of 7.5

Hp, allows the dairy plant to have cold water. The

water passes through a copper evaporator with a

difluoromethane refrigerant (CH

2

F

2

), the pump

returns the water to the ice bank. The mass flow

was calculated with the capacity of the ice bank

of 75 t and with the water density of 1000 kg m

-3

(18). The physical exergy is determined by Equa-

tion 8.

(8)

Where, M4 is the refrigerant mass flow, is

the water heat capacity.

III. RESULTS AND DISCUSSION

The present study aims at the energy optimiza-

tion of the milk pasteurization process by deter-

mining the destruction of exercise and exergy

efficiency in each of the process lines, as shown

17

in Table 5 and 6. Where it is analyzed in the li-

nes of pasteurization, steam generation and cold

bank in the current operating conditions of the

plant tables 1, 2 and 3. The physical and chemical

exergy of the system is established under stan-

dard operating conditions of the plant.

COMPONENTS PHYSICAL EXERGY (kJ s

-1

) EXERGETIC DESTRUCTION (kJ s

-1

) EXERGETIC PERFORMANCE

Reception tank

EX_ph1=0.007467

EX_ph2=0.007467

EX_destA=0 nA=1

Storage tank EX_ph3=0.007467 EX_destB=0 nB=1

Bomb EX_ph4=0.02315 EX_destC=0.0020 nC=0.9018

Filter EX_ph5=0.02091 EX_destD=0.0012 nD=0.9447

Centrifuge

EX_ph6=0.5138

EX_ph7=0.6525

EX_destF=1.56

nF=0.08163

Homogenizer

EX_ph8=0.1959

EX_ph9=0.2815

EX_destG=0.5834 nG=0.128

Storage tank

EX_ph12=27.93

EX_ph13=26

EX_destH=1.932

nH=0.9308

Bomb EX_ph14=29.6 EX_destI=12.96 nI=0.2174

Founder EX_ph15=0 EX_destJ=0 nJ=1

Storage EX_ph16=0 EX_destK=0 nK=1

Heat exchanger EX_destE=29.42 nE= 0.32

Table 5. Results of the exergy balance line of pasteurization

Source: Authors.

Components

PHYSICAL EXERGY

(kJ s

-1

)

CHEMICAL EXERG

(kJ s

-1

)

EXERGETIC DESTRUCTION

(kJ s

-1

)

EXERGETIC PERFORMANCE

Boiler

EX_phI=0.01195

EX_phII=0.4315

EX_chI=240.2

EX_chII=245.9

EX_destN=5.14

nN=0.5405

Condenser EX_phIII=0.3754 EX_destO=0.4479 nO=0.8704

Bomb EX_phIV=0.3768 EX_destP=0.001625 nP=0.1199

Heat exchanger EX_phV=0.2523 EX_destE=0.1245 nE=0.6695

Table 6. Results Exergy's balance in the steam generation line

Source: Authors.

The steam generation and the pasteurization sys-

tem are the system where the highest rate of exer-

gy destruction occurs. The boiler has a value of

destruction of useful chemical energy of 245,9 kJ

s

-1

and the exergy destruction of physical by heat

transfer 5.14 kJ s

-1

and pasteurizer 29.42 kJ s

-1

due

to the sudden change of temperature that occurs

in the plate heat exchanger. Values that can be

attributed to the rapid heat transfer that is given,

and the significant amount of irreversibilities

due to the combustion reaction (16,23).

It should be noted that in industrial boilers, exer-

getic destruction can be reduced by enriching

oxygen and preheating the air that enters the

combustion chamber, helping to reduce irrever-

sibility while maintaining the stable flame tem-

perature (21). However, this possible solution has

a drawback, the increase in exergy loss between

the boiler and the surroundings. In order to ca-

rry out this improvement it is necessary to invol-

ve cogeneration or waste heat utilization systems,

which help to improve the overall efficiency of

the process (24,25).

In the homogenizer where the configurational

entropy of the milk is analyzed as an indicative

of the good performance of the separation of the

fat fraction, it presents an exercise destruction

of 0.584 kJ s

-1

that reflects a good stability in the

whole milk as well as the influence that the Fat

fraction in the chemical exergy of milk (15). The

destruction of mechanical exercise is understood

as the exercise that is not useful for destroying

the fat globules present in the milk at the entran-

ce of the process.

The destruction of exergy in the pasteurizer, due

to the plate exchanger is 29.42 kJ s

-1

generator

due to the high temperature gradients that are

needed to raise the temperature of the milk and

immediately cool it down irreversible genera by

Angamarca, Chuquin, Palmay

18

ISSN 2477-9105 Número 24 Vol.1 (2020)

heat transfer both in and in cooling.

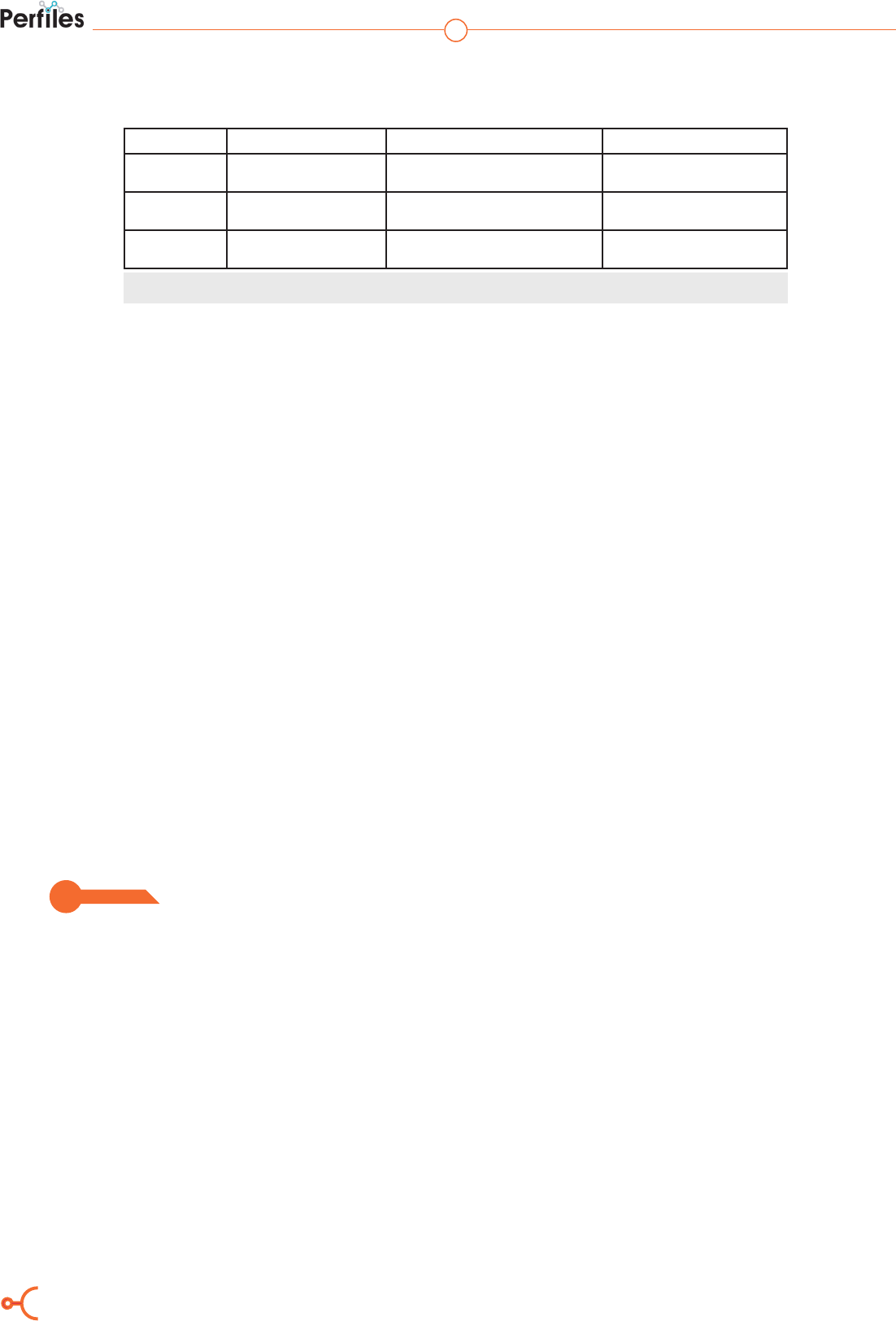

COMPONENTS PHYSICAL EXERG (kJ s

-1

) EXERGETIC DESTRUCTION (kJ s

-1

) EXERGETIC PERFORMANCE

Pack ice

EX_phIX=0.4821

EX_phVI=0.2607

EX_destL=0.1955 nL=0.5715

Bomb EX_phVII=0.2524 EX_destM=0.02471

nM=-0.5059

Heat exchanger EX_phVIII=0.2492 EX_destE=0.0032

nE=0.9873

Table 7. Results Exergy's balance in the cold line

Source: Authors.

Table 7 shows the exergetic analysis in the cold

generation line (ice bank), where the destruction

of exercise of 0.199 related to the rapid and lar-

ge heat transfer that occurs in this component is

observed.

This study is the starting point for future research

that exergoeconomic and exergoenvironmental

analyses, hoping that these approaches will help

to increase the thermodynamic efficiency of the

plant and a decrease in the costs associated with

energy consumption.

IV. CONCLUSIONS

The highest destruction rate of exergy in the pas-

teurization line was in the plate heat exchanger

(29.42 kJ s-1), due to temperature differences in

the thermal shock for pasteurization, in the ge-

neration line steam was in the boiler due to heat

losses (5.14 kJ s-1) and in the cooling system line

was given in the ice bank by rapid heat transfer

(0.21 kJ s

-1

).

The destruction of low exergy in the homogeni-

zer (0.5834 kJ s

-1

) is due to the reduction of the

size of the fat globules in order to stabilize the

milk. The exergy efficiency of the homogenizer

could be improved if the homogenization quality

could be maintained at the lowest possible flow

rate of the milk stream.

The exergetic performance of the boiler (54%)

and the ice bank (57%) generated especially by

the heat transfer are points of optimization for

the improvement in the process. By means of

the exact relation of combustible air and a con-

trol system of oxidizer input, the destruction of

chemical exergy will be reduced, besides that by

means of the best in the distribution and thermal

insulation system of the heat lines, the exergetic

efficiency of the system can be increased of steam

generation. While the ice bank suggests the use

of an industrial cooling system to avoid the use

of ice in the cooling system.

R

eferencias

1. FAO. Leche y Productos.

2. Jokandan MJ, Aghbashlo M, Mohtasebi SS. Comprehensive exergy analysis of an indus-

trial-scale yogurt production plant. Energy [Internet]. 2015;93:1832–51. Available from: http://dx.

doi.org/10.1016/j.energy.2015.10.003

3. Dincer I. Renewable energy and sustainable development: A crucial review. Renew Sustain

energy Rev. 2000;4(2):157–75.

4. Mohammad Rozali NE, Alwi SRW, Manan ZA, Klemeš JJ, Hassan MY. Process Integration

techniques for optimal design of hybrid power systems. Appl Therm Eng. 2013;61(1):26–35.

5. Yildirim N, Genc S. Energy and exergy analysis of a milk powder production system. Ener-

gy Convers Manag [Internet]. 2017;149:698–705. Available from: http://dx.doi.org/10.1016/j.encon-

man.2017.01.064

6. Terehovics E, Veidenbergs I, Blumberga D. Exergy Analysis for District Heating Network.

Energy Procedia. 2017;113:189–93.

7. Cimdina G, Timma L, Veidenbergs I, Blumberga D. Methodologies used for scaling-up

from a single energy production unit to state energy sector. Environ Clim Technol. 2015;15(1):5–21.

19

8. Liu Y, Li Y, Wang D, Liu J. Energy and exergy utilizations of the Chinese urban residen-

tial sector. Energy Convers Manag [Internet]. 2014;86:634–43. Available from: http://dx.doi.or-

g/10.1016/j.enconman.2014.06.037

9. Aghbashlo M, Mobli H, Rafiee S, Madadlou A. A review on exergy analysis of drying pro-

cesses and systems. Renew Sustain Energy Rev [Internet]. 2013;22:1–22. Available from: http://dx.

doi.org/10.1016/j.rser.2013.01.015

10. Singh G, Tyagi V V., Singh PJ, Pandey AK. Estimation of thermodynamic characteristics for

comprehensive dairy food processing plant: An energetic and exergetic approach. Energy. 2020;194.

11. Bühler F, Nguyen T Van, Jensen JK, Holm FM, Elmegaard B. Energy, exergy and advanced

exergy analysis of a milk processing factory. Energy [Internet]. 2018;162:576–92. Available from:

https://doi.org/10.1016/j.energy.2018.08.029

12. Yildirim N, Genc S. Thermodynamic analysis of a milk pasteurization process assisted by

geothermal energy. Energy [Internet]. 2015;90:987–96. Available from: http://dx.doi.org/10.1016/j.

energy.2015.08.003

13. Walmsley TG, Walmsley MRW, Atkins MJ, Neale JR. Improving energy recovery in milk

powder production through soft data optimisation. Appl Therm Eng [Internet]. 2013;61(1):80–7.

Available from: http://dx.doi.org/10.1016/j.applthermaleng.2013.01.051

14. Munir MT, Yu W, Young BR. Can exergy be a useful tool for the dairy industry? [Internet].

Vol. 33, Computer Aided Chemical Engineering. Elsevier; 2014. 1129-1134 p. Available from: http://

dx.doi.org/10.1016/B978-0-444-63455-9.50023-4

15. Mojarab M, Aghbashlo M, Mobli H. Exergetic performance assessment of a long-life milk

processing plant : a comprehensive survey. 2016;

16. Singh G, Singh PJ, Tyagi V V., Barnwal P, Pandey AK. Exergy and thermo-economic analy-

sis of ghee production plant in dairy industry. Energy [Internet]. 2019;167:602–18. Available from:

https://doi.org/10.1016/j.energy.2018.10.138

17. Wołosz KJ. Exergy destruction in the pneumatic pulsator system during one working cycle.

Energy. 2018;146:124–30.

18. Philipp M, Schumm G, Heck P, Schlosser F, Peesel RH, Walmsley TG, et al. Increasing ener-

gy efficiency of milk product batch sterilisation. Energy. 2018;164:995–1010.

19. Dogbe ES, Mandegari M, Görgens JF. Assessment of the thermodynamic performance im-

provement of a typical sugar mill through the integration of waste-heat recovery technologies. Appl

Therm Eng [Internet]. 2019;158(May):113768. Available from: https://doi.org/10.1016/j.applthermal-

eng.2019.113768

20. Guaño Yesenia. “Optimización De La Planta De Lácteos En La Producción De Leche Pas-

teurizada De La Estación Experimental Tunshi.” 2014.

21. Gümüş M, Atmaca M. Environmental Effects Energy and Exergy Analyses Applied to a CI

Engine Fueled with Diesel and Natural Gas Energy and Exergy Analyses Applied to a CI Engine

Fueled with Diesel and Natural Gas. 2013;7036.

22. Huang YW, Chen MQ, Li QH, Xing W. A critical evaluation on chemical exergy and its

correlation with high heating value for single and multi-component typical plastic wastes. Energy.

2018;156:548–54.

23. Gharagheizi F, Ilani-Kashkouli P, Mohammadi AH, Ramjugernath D. A group contribution

method for determination of the standard molar chemical exergy of organic compounds. Energy

[Internet]. 2014;70:288–97. Available from: http://dx.doi.org/10.1016/j.energy.2014.03.124

24. Moejes SN, van Boxtel AJB. Energy saving potential of emerging technologies in milk pow-

der production. Trends Food Sci Technol [Internet]. 2017;60:31–42. Available from: http://dx.doi.

org/10.1016/j.tifs.2016.10.023

25. Sala Lizarraga JMP, Picallo-Perez A. Calculation of physical and chemical exergy. Exergy

Analysis and Thermoeconomics of Buildings. 2020. 183-259 p.

Angamarca, Chuquin, Palmay